- Our products

Materials don’t just happen: we design them

- Our products

Materials don’t just happen: we design them

We specialize in developing additive blends that enhance recycled polymers with targeted properties: from improved impact resistance and optical clarity to UV stability, color control and processability. Each formulation is engineered around performance goals, production constraints, and regulatory needs. Our compounds are not off-the-shelf: they are the result of applied R&D, real-world testing and ongoing technical dialogue with our clients.

- What we work with

Recycled polymers, reimagined

We work with a wide range of thermoplastics, each with its own challenges and potential. Whether it’s the clarity of PET, the flexibility of PE, or the toughness of ABS, our expertise lies in understanding how to improve recycled materials without compromising their functional integrity.

From single-material formulations to complex blends, we develop targeted enhancements that unlock the full value of post-consumer and industrial polymers.

Polymers we work with regularly include:

- PET (Polyethylene Terephthalate)

- PP (Polypropylene)

- PE (Polyethylene – HDPE, LDPE)

- ABS (Acrylonitrile Butadiene Styrene)

- PC (Polycarbonate)

- TPO (Thermoplastic Olefins)

- TPE (Thermoplastic Elastomers)

- PA (Polyamide)

- PVC (Polyvinyl Chloride – evaluated in selected projects)

Working with a specific polymer not showing here? We’re open to exploring custom formulations based on your needs. Let’s find the right approach, together.

Working with a specific polymer not showing here? We’re open to exploring custom formulations based on your needs. Let’s find the right approach, together.

- Our improvements

Key enhancements we offer

Viscosity increase

To improve melt strength and processability, especially in recycled PET.

Impact modification

Enhances toughness and resistance at room and low temperatures for demanding applications.

Optical clarity retention

Maintains transparency even in post-consumer materials or multiple reprocessing cycles.

UV stabilization

Prevents degradation, yellowing and mechanical loss due to external exposure.

Polymer compatibilization

Improves cohesion between different polymer types in blends or coextruded layers.

Processability improvement

Enhances flow, reduces defects, and stabilizes performance during extrusion or molding.

Color tuning and optical correction

For neutral tones, brightness or custom color balance in recycled compounds.

Anti-yellowing performance

Minimizes oxidation-induced discoloration during high-temperature processing.

Mechanical reinforcement

Increases stiffness, load resistance or durability for structural applications.

Surface & aesthetic optimization

Improves appearance, gloss, and finish of final parts.

Need specific properties in your recycled compound? From impact strength to UV resistance or clarity, we engineer the right enhancements for your application. Let’s define the required performance and make it happen.

Need specific properties in your recycled compound? From impact strength to UV resistance or clarity, we engineer the right enhancements for your application. Let’s define the required performance and make it happen.

- Flexible and customizable

Logistics & packaging

Our finished product is a standard cylindrical pellets, 3–4 mm in size, engineered for optimal processability.

We offer full flexibility in packaging and logistics: from industrial-scale deliveries to lab-scale testing. Standard packaging includes 1000 kg big bags, 25 kg bags and 500 kg pallets. Custom formats are available on request.

Global reach

We currently ship to over 15 countries across Europe, Asia, Africa and Latin America.

Flexible packaging

Custom batch sizes and packaging formats available to meet technical or logistical constraints.

- Real applications

Tested, applied, proven: five real-world uses + one

Thermoformed food packaging

R-PET compounds with improved impact resistance and transparency for refrigerated and frozen containers.

Sheet

extrusion

Custom formulations for rigid PET sheets used in thermoforming lines for high-clarity packaging.

Strapping

bands

Recycled PP and PET blends for strong, stable industrial strapping solutions.

Injection-molded products

Enhanced recycled PET compounds derived from medical garments, reused in furniture and garden items.

Building and greenhouse profiles

Impact-resistant PVC alternatives for construction and agricultural applications.

Be the next success case

Let’s develop your next product with smart performance built in.

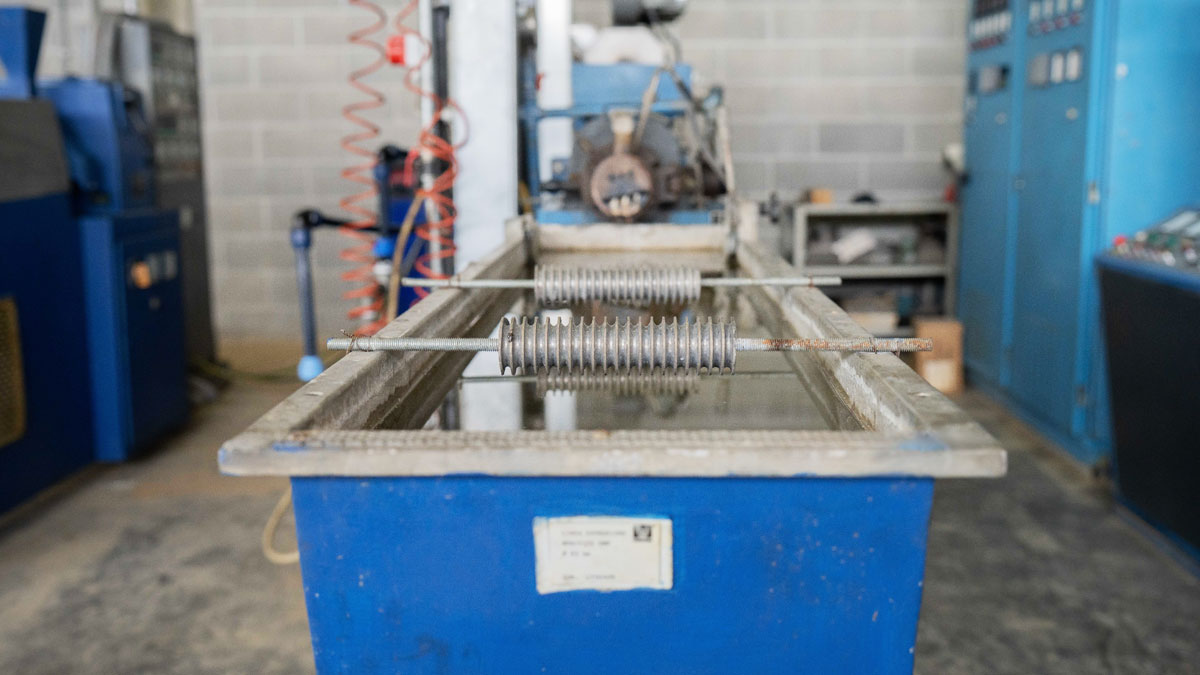

- In-house testing

Where formulations are verified

Belar’s internal lab is integral to our development and quality assurance process. We carry out mechanical and chemical testing on each batch using dedicated equipment, including a dynamometer for tensile strength and elongation at break, and an impact testing machine.

More than just a control step, our lab is a tool for innovation, guiding formulation design and ensuring every material performs as intended.

Sampling protocol & traceability

Sample bars are produced through a proprietary mold and tested in collaboration with a trusted partner workshop. Every production run is sampled at the beginning, middle and end of the cycle, with reference specimens archived for consistency checks.

ISO 9001 quality framework

All laboratory activities are conducted within the framework of our ISO 9001 certified quality management system, ensuring full traceability, repeatability and compliance across every stage of production.